In my previous article I discussed building a mask for NanoDLP using a UV meter that was somewhat cobbled together from stuff that I had laying around. Here I present a slightly more grown up version of said meter!

This would be a fairly small package enclosing an Arduino Nano, connected to a USB power source, a 128x64 LCD display, two push buttons, one LED, a photo resistor, a 10k resistor, and a bluetooth adapter.

The LED (green) will flash when a stable reading is being obtained.

Pressing either button when a stable reading is present will cause a reading to be taken and displayed on the LCD.

The above reading will also be output to the serial port and and broadcast by the bluetooth adapter. The value output will be terminated with a comma.

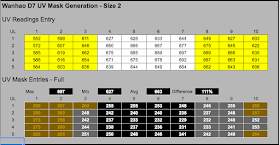

Pressing both buttons will output a newline to the serial port to be broadcast by the bluetooth adapter. In this manner a CSV (comma separated values) buffer can be built for capture on the PC connected to the meter.

The photoresistor mounted on the bottom of the meter will fit into the grid designed and printed for the purpose of measuring UV output of the 3D Printer.

In operation the meter could be used either disconnected, and taking a single reading at a time transcribed from the LCD display, or connected to a computer where the entire stream of readings is buffered and captured.